For our many followers (!!!) we will not be posting another blog until the end of March when we're planning a trip to the Netherlands.

Destiny came into our possession in Sep 2018. In this blog we aim to outline what it takes to own an Elling and describe our adventures aboard her.

Saturday 16 February 2019

Tuesday 12 February 2019

"The two happiest days of a person’s life — the day they bought the boat and the day they sold the boat"

It can certainly be the case that boat ownership is not always plain sailing: there are inevitably ups and down. However, I have always felt a pang of regret and sadness when passing on our previous boats to their new owners.

Our latest "happiest day" occurred at the end of August 2018 when we finally signed the paperwork on a 2007 Elling E4. The survey confirmed she was a fundamentally sound vessel with low hours that had been well cared for throughout her life. As always with boats, there were things that didn't work, things that needed to be upgraded and things we wanted to change. Following a brief handover by the broker we set off from her berth on the River Thames to her new home in Suffolk.

Our latest "happiest day" occurred at the end of August 2018 when we finally signed the paperwork on a 2007 Elling E4. The survey confirmed she was a fundamentally sound vessel with low hours that had been well cared for throughout her life. As always with boats, there were things that didn't work, things that needed to be upgraded and things we wanted to change. Following a brief handover by the broker we set off from her berth on the River Thames to her new home in Suffolk.

After a cautious start, we settled into enjoying the trip down the Thames to Limehouse marina. The Thames proved a delight and has real character - from quaint houses perched along the river banks to iconic buildings dominating the skyline all mixed with great scenery.

|

| Tranqulity |

|

| No prizes for guessing who this belongs to |

|

| A beautiful house boat |

|

| Sights of London |

By late afternoon Destiny was tucked up in her new marina. The following day the weather had turned and the clear skies we had enjoyed turned to rain as we prepared to get lifted.

Now the work begins!

|

How did we come to own an Elling?

Having owned 2 boats since 2005, over the years our views on what we wanted to get from our next boat, and how we would use it, have evolved. We spent several years in the UK and then 7 years in the Med with our Trader 41+2 and loved it.

Being without a boat didn't sit well with me so we bought a nearly new Botnia Targa 35 which we kept in the UK. Much as we loved the Botnia it cemented our developing view that we wanted something more sedate with which we could cruise for extended periods in comfort and with enough room so as not to feel cramped.

Our requirements list included being a Cat A design (ocean-going), preferably single engine with a wing engine for back-up and preferably full displacement. I wanted a boat which was easy to work on and had appropriate access to all the mechanical and electrical systems. We also wanted the boat to have a reasonable range and to be of a well built and robust design which was equipped with all the comforts of home.

These requirements limited our choices since many motor boats, although claiming to be rugged and suitable for offshore passages, really aren't designed or built to stand up to the rigour of the open seas.

We looked at a number of options including our first choice of a Nordhavn 47. Sadly these are few and far between in UK/EU spec so we widened our search. Having looked at a number of Dutch steel boats we eventually had an offer accepted on a Diesel Duck based in the Med. The DDs are a niche design built in China. Sadly, on inspection, the paperwork didn't meet our expectations so we were back to the drawing board.

I'd heard of the Elling brand and seen them at boat shows; however, I'd never really seriously considered them thinking that the engine was too big and access to it and other systems would be too restricted. Fortunately, I met the kind owners of an E3 in a local marina and they showed me around, eulogising all the time about how great their boat was. This whet my appetite sufficiently to look further into the E4. The rest, as they say, is history.

|

| Our Trader in the Ionian |

|

| Our Botnia Targa 35 |

Our requirements list included being a Cat A design (ocean-going), preferably single engine with a wing engine for back-up and preferably full displacement. I wanted a boat which was easy to work on and had appropriate access to all the mechanical and electrical systems. We also wanted the boat to have a reasonable range and to be of a well built and robust design which was equipped with all the comforts of home.

These requirements limited our choices since many motor boats, although claiming to be rugged and suitable for offshore passages, really aren't designed or built to stand up to the rigour of the open seas.

We looked at a number of options including our first choice of a Nordhavn 47. Sadly these are few and far between in UK/EU spec so we widened our search. Having looked at a number of Dutch steel boats we eventually had an offer accepted on a Diesel Duck based in the Med. The DDs are a niche design built in China. Sadly, on inspection, the paperwork didn't meet our expectations so we were back to the drawing board.

I'd heard of the Elling brand and seen them at boat shows; however, I'd never really seriously considered them thinking that the engine was too big and access to it and other systems would be too restricted. Fortunately, I met the kind owners of an E3 in a local marina and they showed me around, eulogising all the time about how great their boat was. This whet my appetite sufficiently to look further into the E4. The rest, as they say, is history.

Destiny - the boat

To quote the manufacturer's blurb "The E-Series reach new levels of safety and luxury in contemporary yacht design, built from Twaron to the demanding CE Category A (Ocean) standard, that's as tough as a lifeboat!" To prove the point the company's owner underwent a capsize test - see the link below.

https://www.youtube.com/watch?v=bfhV87kppAE

Not that I would ever wish to put it to the test but it's a good publicity stunt!

DESTINY

Other that's self-righting ability which makes her well-suited for rougher waters, Destiny is equipped with an electrically operate aerial/radar mount facilitating an air draught of 3.45 metres which allows access to European canals down to the Med. Great flexibility for a boat of this size.Vital Statistics

Interior

Cherry wood interior. 6 berths in 3 cabins - owner's cabin aft with a queen size island berth and en-suite, a mid-cabin with 2 bunks, and a forward cabin with 2 single berths. There is a further day head and shower off the saloon. Large saloon - seats 8 comfortably. The pilothouse has a helm seat and seating for 3 more. 3 wine cellars! TV lift in saloon. Wall hung TV in owner's suite. AM/FM radio + CD. 2 x Techma electric heads. Heated towel rails in heads. 220volt sockets throughout. Bug nets for all windows/hatches. Double glazing. Galley with electric oven and ceramic hob, microwave, large fridge/freezer and Miele washer/dryer.

Outside there are 2 generous storage lockers/seats situated on a large after deck (approx 4 square metres) covered by a removable bimini. Teak table. Decks are laid with flexi-teak. Outside hot and cold shower. Electrically operated hard top sliding roof with pneumatic seal. Integrated seat on front deck for 2. Sun bed on front deck. Deck lights and courtesy lights. Hydraulic passarelle + remotes.

Technical

Main engine - Volvo Penta D6 435hp and 352 hours when bought

Wing engine - Volvo Penta D1 27hp and 55 hours when bought. Separate 100 litre fuel tank and drive.

Generator - Mastervolt 10 kVA and 190 hours when bought

Full reverse cycle AC - 40,000 BTU

1500 litres of fuel

Holding tank 150 litres

Water tank 850 litres

24 volt electrical system

25 kg Delta anchor plus 50 metres of 10mm chain

Chain counter

Bow and stern thrusters

1500W inverter

75A battery charger

420Ah domestic batteries

100Ah start batteries/stern thruster

Separate batteries and chargers for the generator and bow thruster

24 volt anchor windlass

Automatic engine fire system

Water alarm

Instruments

Rear view camera

Simrad plotter and radar - to be replaced

AIS

Wind, speed and depth data

Battery monitor

Yacht controller for easy mooring

Autopilot + remote

Compasses - electrical and analog

DSC radio

Handheld radio

Handhelp GPS

2 x barometers

Wempe Clock, hydrometer and thermometer

Safety

8 man liferaft

Lifejackets

EPIRBs

SART transponder

Navtex

Numerous fire extinguishers

Bow search light

Dimensions

LOA 14.95m

Draft 1.2m

Air draft 3.45m

Beam 4.25m

Max speed 16-18kts

Economic cruise up to 9kts

Advice: Skip this page if you have no interest in upgrades/maintenance/improvements

These pages outline the work carried out on Destiny reflecting the results of the survey and improvements and upgrades we wished to make. Elling provide a manual which outlines the system on board and the previous owner had a good selection of manuals for most of the equipment. However, there's nothing like getting your hands dirty to really get to know your boat, how it works and how well it was designed and built. I have to say I have been impressed.

Key survey results:

Saildrive Leak

The most pressing job was to address a leak that had been identified allowing water into the Saildrive unit - the drive for the wing (back-up) engine. The Saildrive had recently been removed and, on investigation, it appeared the unit had not been properly reassembled.

Fortunately, the agents who undertook the work agreed to pay for the repair so the unit was removed and dismantled in the local agent's workshop. It became clear that a gasket had been fixed the wrong way around thus allowing water to ingress.

Here you can see the the gasket, in green, is fitted 180 degs out of position.

The company who carried out the original work admitted the "engineer" who did the job had since left!

Fortunately, no more damage occurred as a result of the water ingress.

While the Saildrive was out I took the opportunity to clean up and antifoul

the folding prop using Velox primer and 2 top coats in black.

The last 2 pictures show what a little TLC and time can do

As with many jobs on boats, you solve one problem and another arises. In order to remove the Saildrive the wing engine had to be move forward. In doing this we noticed some corrosion on the heat exchanger where it meets the exhaust elbow. Sadly this was not picked up on the survey. Examination confirmed our fears that the heat exchanger and elbow needed replacing. This was duly done and, for good measure, I also changed the exhaust muffler whose drain plug had been broken off and been glued into place. Perhaps a reason why the heat exchanger corroded!

We now have complete faith in the wing engine and ancillary components.

Generator tidy up

Although the generator looked in great shape overall the raw water pump was leaking. This was removed, cleaned up, and the impeller and seals were replaced and refitted.

Corrosion on the front plate of the pump

Before the clean up

After some TLC

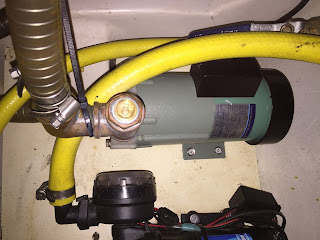

Aircon raw water pump clean up

The pump sits directly under the engine room external air vent so is open to a barrage of moist salty air. As a result it is susceptible to corrosion. As you can see from the pictures the bleed valve had corroded beyond repair and paint had been eaten away.

The pump sits directly under the engine room external air vent so is open to a barrage of moist salty air. As a result it is susceptible to corrosion. As you can see from the pictures the bleed valve had corroded beyond repair and paint had been eaten away.

The renovated pump with new bleed valve and paint

Other maintenance work

Prop removal and Cutlass bearing change

Although we experienced no appreciable vibration from the prop shaft during our delivery trip, on inspection there was a little more movement between the prop shaft and cutlass bearing than I was content to leave for another season. Since we were planning to do a fair bit of cruising over the coming year I decided we should change it. While the prop was off I took the opportunity to clean it up and antifoul it with Velox.

The hub of the prop was heated in order to help free it from the shaft.

Corrosion in engine compartment

In general, the boat was in really nice condition when we picked her up. She has been lightly used and well maintained. However, although the engine sits on the centreline of the boat, the remainder of the engine room, housing the generator, aircon unit and a set of through-hull fittings, pumps and pipes is on the starboard side and is also home to the engine room air vent. This allows heavily laden salt air to enter and attack anything that isn't protected.

In general, the boat was in really nice condition when we picked her up. She has been lightly used and well maintained. However, although the engine sits on the centreline of the boat, the remainder of the engine room, housing the generator, aircon unit and a set of through-hull fittings, pumps and pipes is on the starboard side and is also home to the engine room air vent. This allows heavily laden salt air to enter and attack anything that isn't protected.

I removed and replaced all the pipe clips and removed the corrosion from the fittings. I also gave the pipes/hoses a good clean. Having removed all the through-hull fitting levers these were prepped and painted using Hammerite and then sprayed with white grease. We shall see how well, or not, this protects them. Now that everything is cleaned up it should be a fairly simple, routine task to keep it all in good condition.

All clean, free from corrosion and new clamps fitted

All other through-hulls and fittings were in excellent condition and needed no work. Result!

Replace gland packing

The last job before returning Destiny to the water was to change the stuffing box (gland) packing. This should have been a simple process of removing the old and replacing it with new. Not so. The "stuff" in the stuffing box had probably been their since Pontious was a "pilot" and proved very difficult to remove. Having tried numerous tools it eventually relented and the new "stuff" went in without a hitch. Perhaps this too will last another 12 years!!

General maintenance

While she was chocked I antifouled the hull and changed the anodes. We used Hempel Tiger Xtra: it was the easiest antifoul to apply I ever used and we'll see how it stands up over the season. Once Destiny was back in the water I set about servicing all 3 engines - main, wing and generator.

This really did prove to be a very simple and straight forward job. Access was easy and the concerns I'd had previously about being able to "get at stuff" for maintenance and repair really did evaporate. Elling have been clever in placing easily removable panels where you need them for all routine maintenance tasks. Furthermore, they also provide access to anything that might need to be accessed for non-routine maintenance. This is done by utilising screw on panels wherever anything is covered up. Great design and planning.

Service AirCon

I got a guy to come over and check out the AC system. I had read the ancient manual written before the days of simplicity and coherent pros but couldn't get it to work properly. After some faffing about he identified it had been put into a seldom used mode which prevented it from heating. Having reset the controller it fired up instantly and behaved exactly as advertised. Bliss. He was also kind enough to explain the more intricate subtleties of the system so I am now an instant expert!!

Oil pump reverse switch

The main engine has an electric pump operated by a push button which is designed to make life easy during an oil change. A simple press of the button sucks all the old oil out of the engine. No mess and very quick and easy. However, refilling is not as straight forward. The traditional manual method is employed which when trying to lift a 25 litre can of oil in an awkward, restricted position invariably ends up with a mess in the bilge. The picture below shows a simple 3 way switch I wired in so that the pump can be used to fill the engine as well as remove the engine oil. I'm all for making life easy!

New Battery Relay Fitted

The relay that switches the battery charger between the main/house batteries and the engine start batteries failed. It was a simple job to replace. We took the opportunity to beef it up with a Victron Energy Cyrix-ct 12/24v-230A intelligent battery combiner so hopefully we shouldn't have any problems for the foreseeable future.

The relay is the little black box in the centre of the shot.

New battery charger for bow thruster

The bow thruster batteries had been changed just prior to the survey in the belief that they were faulty. It turns out that the charger was at fault. We swapped it out for a nice new model (Victron Blue Power IP65) that you can monitored from your phone. This is handy since it sits behind a panel in the front cabin.

Pic of charger

Fixed leak from steering binnacle

The steering binnacle has leaked slightly leak since we bought the boat. This was another quick fix: remove the steering wheel, take out the binnacle, tighten the hydraulic couplings, put it back together.

Fit a second latch to radar/aerial mount

The aerial/radar platform is latched into position and releasing the latch allows the electronic lowering of the platform to reduce the air draft to 3.45metres. For some reason, there is only one latch located on the port side of the platform. This results in the platform lying out of square when the latch is engaged. To remedy this I fitted another latch on the starboard side of the platform.

The starboard side of the platform didn't sit flush with the frame

Fitting another latch solved the problem

Fitted new microwave

There was no microwave on board when we bought the boat but the wiring and space was available.

Fix leak from sliding roof

I came back to the boat after some heavy rain and found that water had been running down the outside of the electrical panel - not good news! It turned out that the pipe which drains the channel the roof rails sit in had broken free from the gutter. Reapplying the sealant quickly fixed the problem.

Pic of fix

Sowing!

The bimini had just been replaced before we bought the boat but its cover needed to be repaired along with the cover for the deck table. It's amazing what you can put your mind to when the need arises. Having mastered how to thread the sowing machine (the hardest part), there was no stopping me!

Deck table refurb

On the aft deck sits a 4-piece folding teak deck table. This is a serious piece of kit and probably depleted a rain forest in its making. It was in desperate need or a refurb so I took it back to my workshop, rubbed it down and coated it in Oslo oil that provides excellent UV protection. It now looks like new.

Key survey results:

Saildrive Leak

The most pressing job was to address a leak that had been identified allowing water into the Saildrive unit - the drive for the wing (back-up) engine. The Saildrive had recently been removed and, on investigation, it appeared the unit had not been properly reassembled.

|

| An oil leak from the base of the Saildrive indicated all was not well during the survey |

Here you can see the the gasket, in green, is fitted 180 degs out of position.

The company who carried out the original work admitted the "engineer" who did the job had since left!

Fortunately, no more damage occurred as a result of the water ingress.

While the Saildrive was out I took the opportunity to clean up and antifoul

the folding prop using Velox primer and 2 top coats in black.

The last 2 pictures show what a little TLC and time can do

As with many jobs on boats, you solve one problem and another arises. In order to remove the Saildrive the wing engine had to be move forward. In doing this we noticed some corrosion on the heat exchanger where it meets the exhaust elbow. Sadly this was not picked up on the survey. Examination confirmed our fears that the heat exchanger and elbow needed replacing. This was duly done and, for good measure, I also changed the exhaust muffler whose drain plug had been broken off and been glued into place. Perhaps a reason why the heat exchanger corroded!

|

| The damaged muffler |

Generator tidy up

Although the generator looked in great shape overall the raw water pump was leaking. This was removed, cleaned up, and the impeller and seals were replaced and refitted.

Corrosion on the front plate of the pump

|

Before the clean up

|

After some TLC

Aircon raw water pump clean up

The pump sits directly under the engine room external air vent so is open to a barrage of moist salty air. As a result it is susceptible to corrosion. As you can see from the pictures the bleed valve had corroded beyond repair and paint had been eaten away.

The pump sits directly under the engine room external air vent so is open to a barrage of moist salty air. As a result it is susceptible to corrosion. As you can see from the pictures the bleed valve had corroded beyond repair and paint had been eaten away.The renovated pump with new bleed valve and paint

Other maintenance work

Prop removal and Cutlass bearing change

Although we experienced no appreciable vibration from the prop shaft during our delivery trip, on inspection there was a little more movement between the prop shaft and cutlass bearing than I was content to leave for another season. Since we were planning to do a fair bit of cruising over the coming year I decided we should change it. While the prop was off I took the opportunity to clean it up and antifoul it with Velox.

|

| Prop off |

|

| Cutlass removed |

|

| Prop ready for re-fitting |

In general, the boat was in really nice condition when we picked her up. She has been lightly used and well maintained. However, although the engine sits on the centreline of the boat, the remainder of the engine room, housing the generator, aircon unit and a set of through-hull fittings, pumps and pipes is on the starboard side and is also home to the engine room air vent. This allows heavily laden salt air to enter and attack anything that isn't protected.

In general, the boat was in really nice condition when we picked her up. She has been lightly used and well maintained. However, although the engine sits on the centreline of the boat, the remainder of the engine room, housing the generator, aircon unit and a set of through-hull fittings, pumps and pipes is on the starboard side and is also home to the engine room air vent. This allows heavily laden salt air to enter and attack anything that isn't protected.

Here are a selection of the worst affected pieces.

All clean, free from corrosion and new clamps fitted

All other through-hulls and fittings were in excellent condition and needed no work. Result!

Replace gland packing

The last job before returning Destiny to the water was to change the stuffing box (gland) packing. This should have been a simple process of removing the old and replacing it with new. Not so. The "stuff" in the stuffing box had probably been their since Pontious was a "pilot" and proved very difficult to remove. Having tried numerous tools it eventually relented and the new "stuff" went in without a hitch. Perhaps this too will last another 12 years!!

General maintenance

While she was chocked I antifouled the hull and changed the anodes. We used Hempel Tiger Xtra: it was the easiest antifoul to apply I ever used and we'll see how it stands up over the season. Once Destiny was back in the water I set about servicing all 3 engines - main, wing and generator.

This really did prove to be a very simple and straight forward job. Access was easy and the concerns I'd had previously about being able to "get at stuff" for maintenance and repair really did evaporate. Elling have been clever in placing easily removable panels where you need them for all routine maintenance tasks. Furthermore, they also provide access to anything that might need to be accessed for non-routine maintenance. This is done by utilising screw on panels wherever anything is covered up. Great design and planning.

Service AirCon

I got a guy to come over and check out the AC system. I had read the ancient manual written before the days of simplicity and coherent pros but couldn't get it to work properly. After some faffing about he identified it had been put into a seldom used mode which prevented it from heating. Having reset the controller it fired up instantly and behaved exactly as advertised. Bliss. He was also kind enough to explain the more intricate subtleties of the system so I am now an instant expert!!

Oil pump reverse switch

The main engine has an electric pump operated by a push button which is designed to make life easy during an oil change. A simple press of the button sucks all the old oil out of the engine. No mess and very quick and easy. However, refilling is not as straight forward. The traditional manual method is employed which when trying to lift a 25 litre can of oil in an awkward, restricted position invariably ends up with a mess in the bilge. The picture below shows a simple 3 way switch I wired in so that the pump can be used to fill the engine as well as remove the engine oil. I'm all for making life easy!

The relay that switches the battery charger between the main/house batteries and the engine start batteries failed. It was a simple job to replace. We took the opportunity to beef it up with a Victron Energy Cyrix-ct 12/24v-230A intelligent battery combiner so hopefully we shouldn't have any problems for the foreseeable future.

The relay is the little black box in the centre of the shot.

New battery charger for bow thruster

The bow thruster batteries had been changed just prior to the survey in the belief that they were faulty. It turns out that the charger was at fault. We swapped it out for a nice new model (Victron Blue Power IP65) that you can monitored from your phone. This is handy since it sits behind a panel in the front cabin.

Pic of charger

Fixed leak from steering binnacle

The steering binnacle has leaked slightly leak since we bought the boat. This was another quick fix: remove the steering wheel, take out the binnacle, tighten the hydraulic couplings, put it back together.

Fit a second latch to radar/aerial mount

The aerial/radar platform is latched into position and releasing the latch allows the electronic lowering of the platform to reduce the air draft to 3.45metres. For some reason, there is only one latch located on the port side of the platform. This results in the platform lying out of square when the latch is engaged. To remedy this I fitted another latch on the starboard side of the platform.

The starboard side of the platform didn't sit flush with the frame

Fitting another latch solved the problem

Fitted new microwave

There was no microwave on board when we bought the boat but the wiring and space was available.

Fix leak from sliding roof

I came back to the boat after some heavy rain and found that water had been running down the outside of the electrical panel - not good news! It turned out that the pipe which drains the channel the roof rails sit in had broken free from the gutter. Reapplying the sealant quickly fixed the problem.

Pic of fix

Sowing!

The bimini had just been replaced before we bought the boat but its cover needed to be repaired along with the cover for the deck table. It's amazing what you can put your mind to when the need arises. Having mastered how to thread the sowing machine (the hardest part), there was no stopping me!

Deck table refurb

On the aft deck sits a 4-piece folding teak deck table. This is a serious piece of kit and probably depleted a rain forest in its making. It was in desperate need or a refurb so I took it back to my workshop, rubbed it down and coated it in Oslo oil that provides excellent UV protection. It now looks like new.

Upgrades and Improvements

Before we bought the boat we knew we would want to upgrade and modernise the navigation and other systems. This is where the main expense occurred.

Chartplotter, Radar and Sonar

Destiny came with a Simrad chart plotter of some vintage. Although perfectly functional, it was not intuitive and fell way behind modern systems in terms of capability, interoperability and usability. It had to go. Changing the chart plotter also meant having to change the radar since the new system could not be easily integrated with the old.

The old system

After trailing the web, speaking to numerous people and visiting the Southampton Boat Show we opted for a Raymarine system. Our previous boat was equipped with a beautiful Garmin touch screen plotter; however, in rough conditions we found this very difficult to use. We wanted a touch screen but also felt that having a traditional option of "buttons and dials" would be greatly advantageous. Of all the options we found the Raymarine suited us best. We opted for an Axiom Pro 12 chartplotter and a Quantum 2 doppler radar. We also added a new sonar.

The decision regarding what to buy was relatively straight forward. Fitting it was another matter. The old depth sounder had to be removed but the Sikaflex was doing a sterling job of holding it in place. I had to resort to drilling out the old unit. Fortunately, the new sonar had a slightly larger diameter so I had a bit of tolerance to play with. Once removed, fitting the unit was easy. Fitting the radar and chartplotter was also relatively straight forward. The problems arose trying to feed the leads from the new equipment. We took out the captains chair, removed the wall panels, removed some ceiling panels and a panel behind the settee in the pilothouse. We also had to remove the storage box on the deck in order to thread the cables around a corner designed to stop water ingress - well, it stopped us threading the cables anyway! Eventually it was all done. Linking it all together didn't take the expert from the marine equipment shop long at all. We then had to get the boat back to looking like a boat rather than a bomb site.

We now have a super chart plotter linked via a cable (and wifi, if required) to the radar, AIS, engine data, sonar and other equipment.

Fusion Radio

The radio/cd player that came with the boat was of the type that would not have been out of place in a 1980s car - big graphic equaliser, flashing lights, way too many buttons and not capable of being linked to anything. It had to go. We replaced it with a Garmin Fusion RA70N which can be linked to the chart plotter and can be driven by a Bluetooth connection form our iPhones/iPads. Great for Spotify etc.

Battery Monitoring

Destiny has a traditional battery monitor that is useful for seeing how much power is being used or put back into the system. It is less helpful in providing an accurate determination of the SOC (state of charge) of the main battery bank. An accurate SOC is important since it helps inform you when you need to top up the batteries. Allowing the batteries to run too low adds another discharge cycle to the bank which shortens its useful life. We chose the SmartGauge system which I had fitted to our previous boat. It's very simple to fit and meets our needs well.

Galvanic isolator

The boat was not fitted with a galvanic isolator. These are an important and cost effective way of helping to protect the expensive metal fitting on a boat from corrosion caused by stray electric currents in the water. We fitted one.

Safety

Destiny came with a really good selection of safety equipment but we added a personal EPIRB, life jackets and an additional medical box.

Still to come

There are still a few planned purchases on the cards. We need a tender, outboard and a davit system to launch and retrieve the tender. This will be essential when we move to the Med but is not pressing in UK waters. Additionally, I would like to get some scuba kit to supplement the wetsuit and snorkelling equipment that is already on board.

No doubt there will be other things that come to mind after we have used the boat for an extended period.

Chartplotter, Radar and Sonar

Destiny came with a Simrad chart plotter of some vintage. Although perfectly functional, it was not intuitive and fell way behind modern systems in terms of capability, interoperability and usability. It had to go. Changing the chart plotter also meant having to change the radar since the new system could not be easily integrated with the old.

The old system

After trailing the web, speaking to numerous people and visiting the Southampton Boat Show we opted for a Raymarine system. Our previous boat was equipped with a beautiful Garmin touch screen plotter; however, in rough conditions we found this very difficult to use. We wanted a touch screen but also felt that having a traditional option of "buttons and dials" would be greatly advantageous. Of all the options we found the Raymarine suited us best. We opted for an Axiom Pro 12 chartplotter and a Quantum 2 doppler radar. We also added a new sonar.

|

| The new kit |

We now have a super chart plotter linked via a cable (and wifi, if required) to the radar, AIS, engine data, sonar and other equipment.

Fusion Radio

The radio/cd player that came with the boat was of the type that would not have been out of place in a 1980s car - big graphic equaliser, flashing lights, way too many buttons and not capable of being linked to anything. It had to go. We replaced it with a Garmin Fusion RA70N which can be linked to the chart plotter and can be driven by a Bluetooth connection form our iPhones/iPads. Great for Spotify etc.

Battery Monitoring

Destiny has a traditional battery monitor that is useful for seeing how much power is being used or put back into the system. It is less helpful in providing an accurate determination of the SOC (state of charge) of the main battery bank. An accurate SOC is important since it helps inform you when you need to top up the batteries. Allowing the batteries to run too low adds another discharge cycle to the bank which shortens its useful life. We chose the SmartGauge system which I had fitted to our previous boat. It's very simple to fit and meets our needs well.

Galvanic isolator

The boat was not fitted with a galvanic isolator. These are an important and cost effective way of helping to protect the expensive metal fitting on a boat from corrosion caused by stray electric currents in the water. We fitted one.

Safety

Destiny came with a really good selection of safety equipment but we added a personal EPIRB, life jackets and an additional medical box.

Still to come

There are still a few planned purchases on the cards. We need a tender, outboard and a davit system to launch and retrieve the tender. This will be essential when we move to the Med but is not pressing in UK waters. Additionally, I would like to get some scuba kit to supplement the wetsuit and snorkelling equipment that is already on board.

No doubt there will be other things that come to mind after we have used the boat for an extended period.

Subscribe to:

Posts (Atom)